1. Généralités

Avec la promotion et l'application des technologies d'automatisation des sous-stations, le nombre de sous-stations sans personnel augmente. Les appareillages haute tension de ces sous-stations adoptent une structure entièrement étanche. Lors d'un fonctionnement prolongé, des pièces telles que les contacts des interrupteurs et les connexions des barres omnibus chauffent en raison du vieillissement ou d'une résistance de contact excessive. L'impossibilité de contrôler la température de ces pièces entraîne une dégradation progressive des conditions de fonctionnement des équipements et accroît considérablement le risque d'accidents, comme la surchauffe des contacts d'entrée et de sortie des tiroirs et des armoires d'entrée des appareillages basse tension. Il est donc essentiel de mettre en œuvre une surveillance thermique fiable et un contrôle intelligent. À cet égard, notre gamme de produits de mesure de température sans fil, conçue pour la surveillance continue de la température de chaque nœud électrique, permet d'éviter efficacement les défaillances graves, sources de blessures et de pertes économiques pour les utilisateurs.

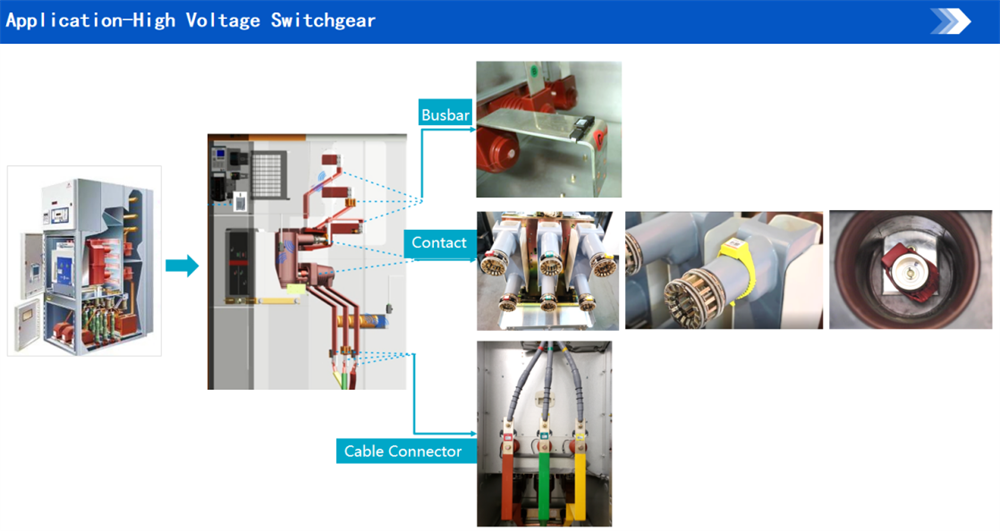

2. Application dans les appareillages de commutation haute tension

• Mesure de la température des connecteurs de câble

• Mesure de la température de contact

• Mesure de la température des barres omnibus

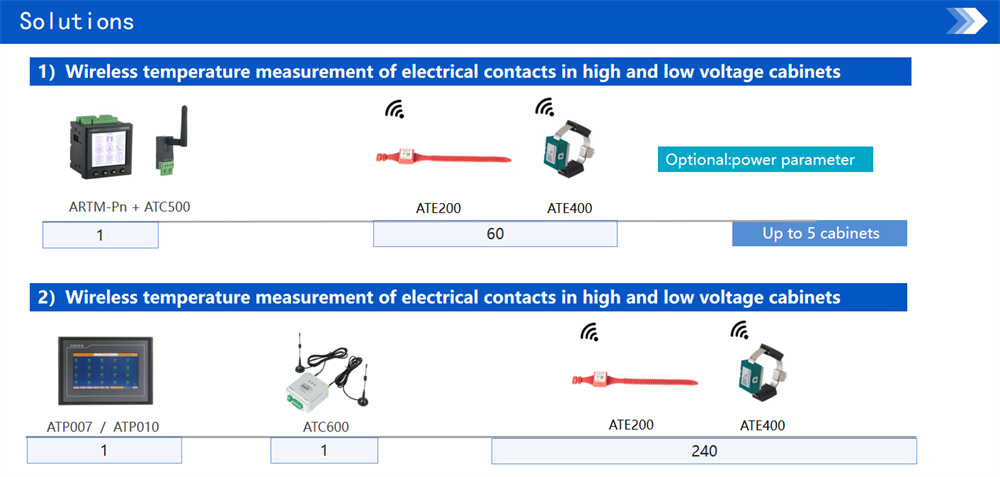

Solution:

Sélection rapide des produits :

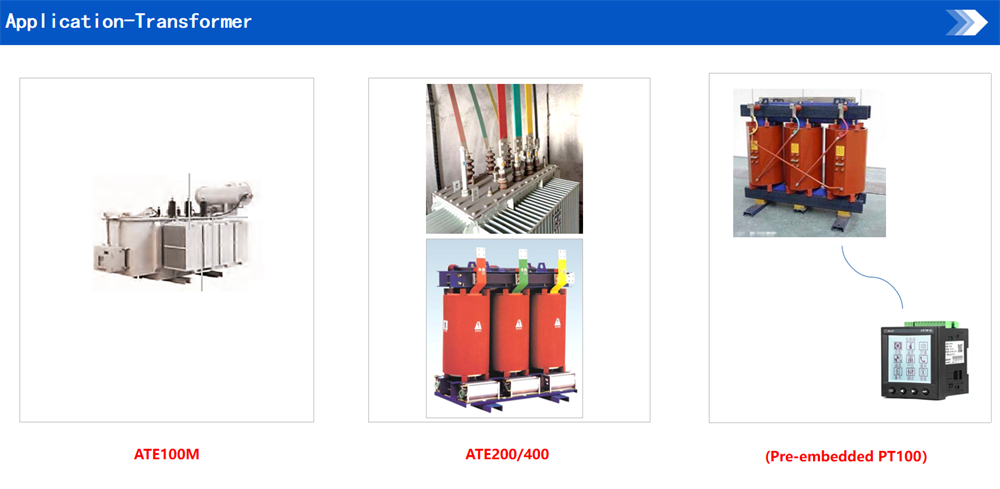

3. Application dans le transformateur

• Mesure de la température de surface du transformateur

• Mesure de la température des connecteurs du transformateur

• Mesure de la température des enroulements internes du transformateur

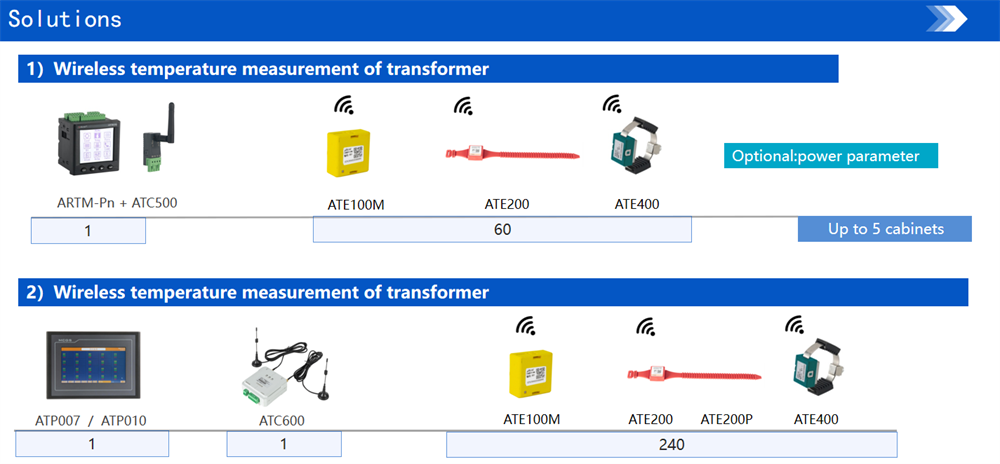

Solution:

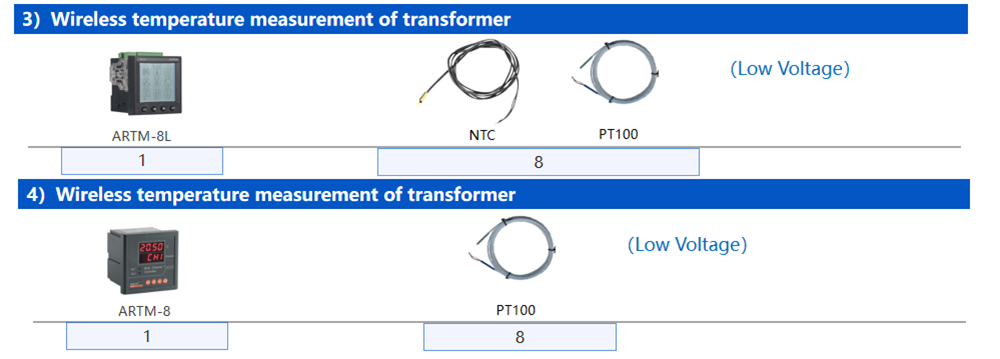

Sélection rapide des produits :

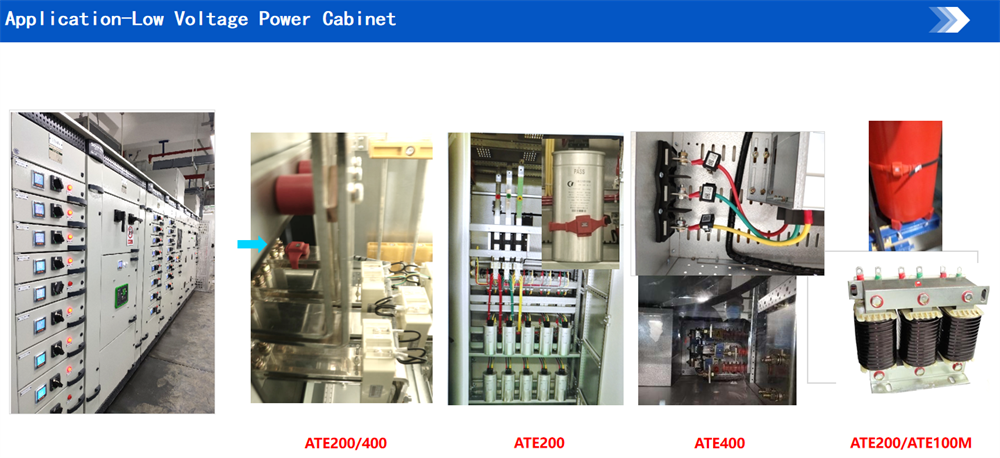

4. Application dans une armoire électrique basse tension

• Mesure de la température des connecteurs CB/barres omnibus

• Mesure de la température de surface du condensateur

• Mesure de température des jonctions de câbles

• Mesure de la température de surface du réacteur

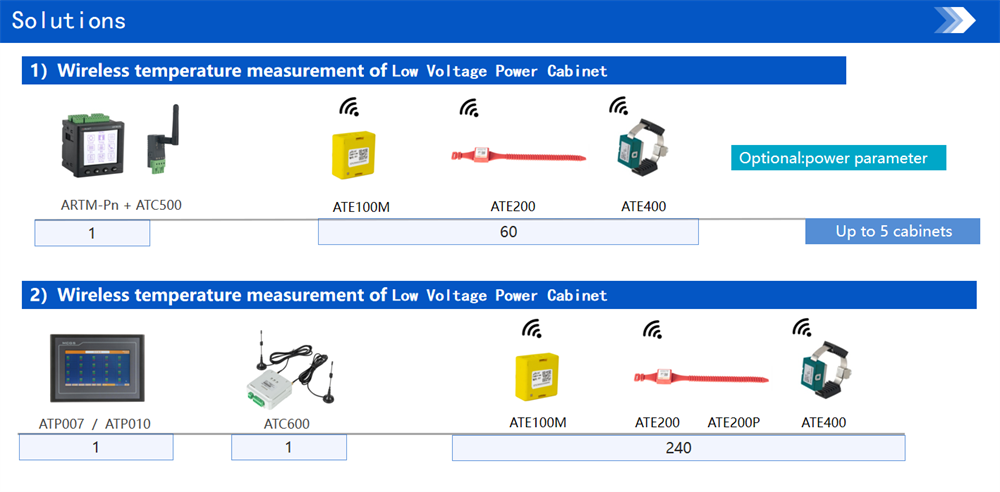

Solution:

Sélection rapide des produits :

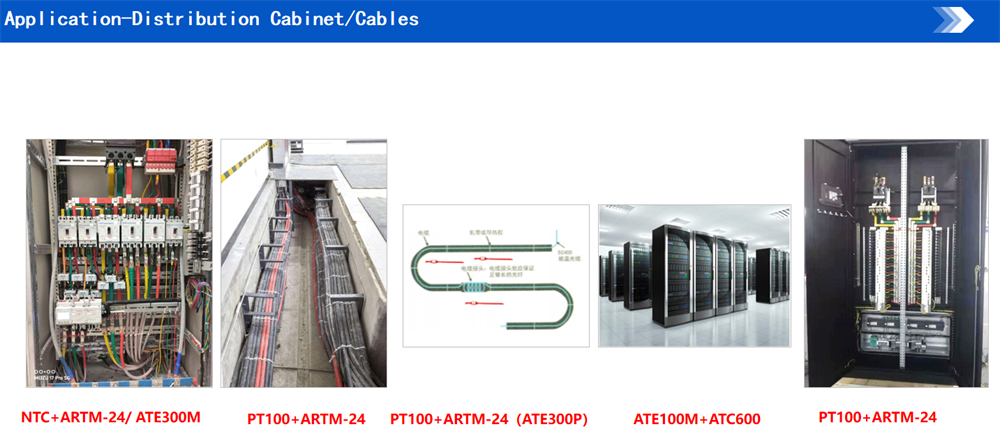

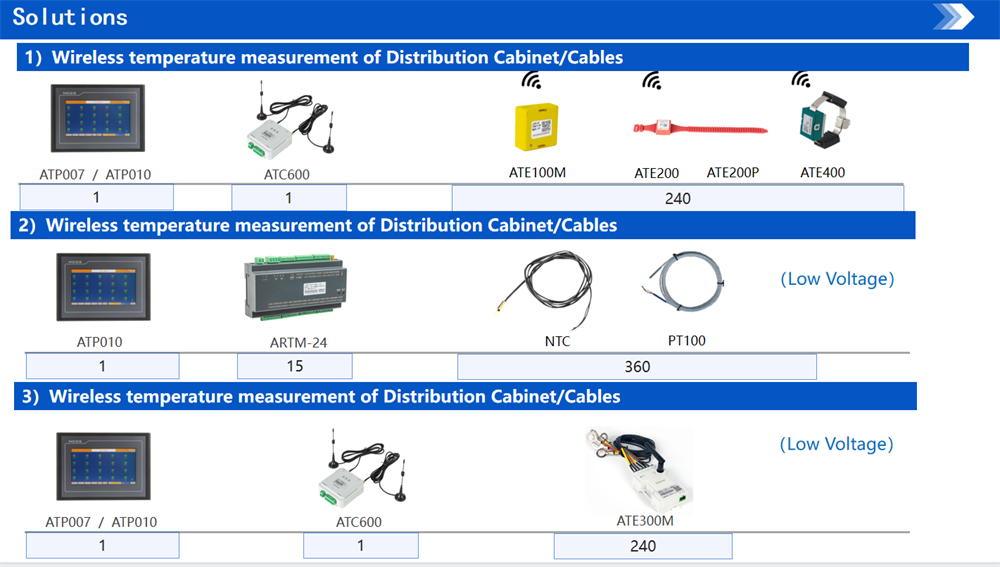

5. Application dans l'armoire de distribution/câbles

• Mesure de la température de l'armoire de distribution terminale

• Mesure de la température des tranchées de câbles

• Mesure de la température de l'enveloppe des câbles/ponts/barreaux électriques en intérieur

• Mesure de la température des serveurs de centres de données

• Mesure de la température des connecteurs des baies de centres de données

Solution:

Sélection rapide des produits :

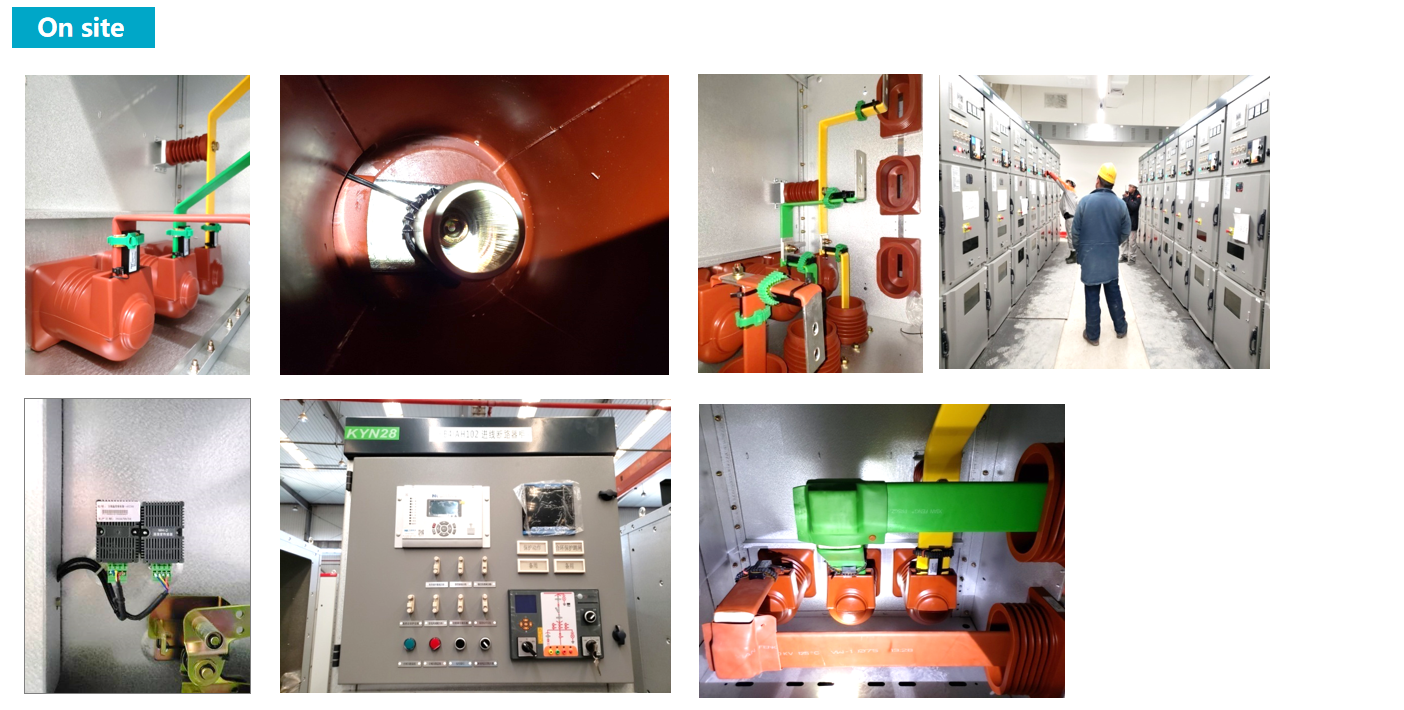

Photo prise sur place :

En résumé, afin de prévenir l'augmentation de la résistance de contact et la surchauffe des contacts qui se forment pendant le fonctionnement en raison de l'oxydation, du desserrage, de la poussière et d'autres facteurs qui causent des risques pour la sécurité, d'améliorer la sécurité des équipements, de refléter en temps opportun, en continu et avec précision les conditions de fonctionnement des équipements, de réduire le taux d'accidents des équipements, la surveillance de la température des appareillages de commutation haute et basse tension, des joints de câbles, des contacts de disjoncteurs, des interrupteurs à couteau, des têtes intermédiaires de câbles haute tension, des transformateurs secs, des équipements basse tension à courant élevé et autres est très nécessaire.

Date de publication : 29 avril 2025