1. Market Size and Growth Drivers

The global DC energy meter market has grown steadily over the past 2025, with an estimated market size of $1.4 billion and a CAGR exceeding 15%. This growth is primarily driven by demand from multiple sectors, including EV charging stations, photovoltaic (PV)/energy storage, 5G telecom tower base stations, and DC power distribution. Specifically, the expansion of charging infrastructure is fueled by the explosive growth of new energy vehicles, while policy support accelerates the adoption of PV and energy storage systems. Additionally, the construction of 5G telecom tower base stations further boosts demand. These multiple drivers collectively propel the sustained and positive development of the global DC meter market.

2. Pain Points and Demand Analysis by Scenario

Core requirements for DC meters across different scenarios:

EV Charging Stations: Require cost-effectiveness, full certification, and robust performance.

Telecom Tower Base Stations: Demand compact size and strong electromagnetic interference (EMI) resistance.

PV and Energy Storage Systems: Large-scale energy storage power stations require monitoring of high voltages up to 1500V. Hall sensors are utilized to ensure safe, reliable, and accurate measurements.

DC Power Distribution: Need to support a wide voltage range (48V to 1000V), allow for panel mounting, and support multi-protocol communication to ensure compatibility.

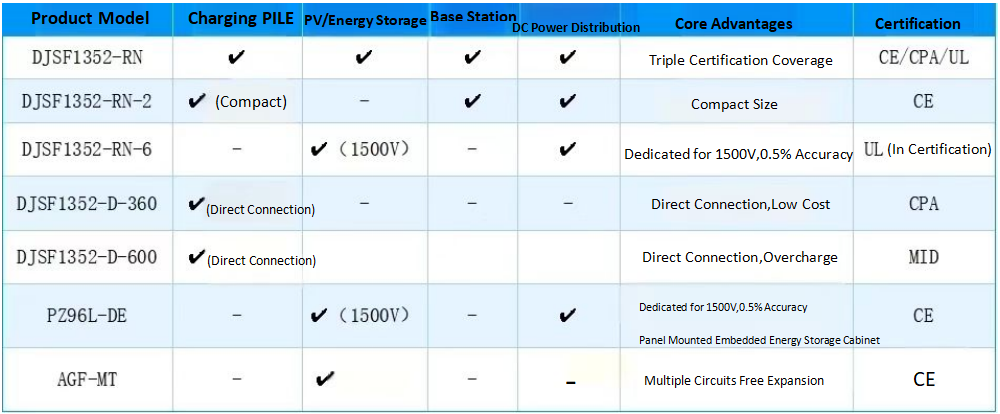

3. Product Portfolio and Scenario Adaptation

4. Product technology analysis

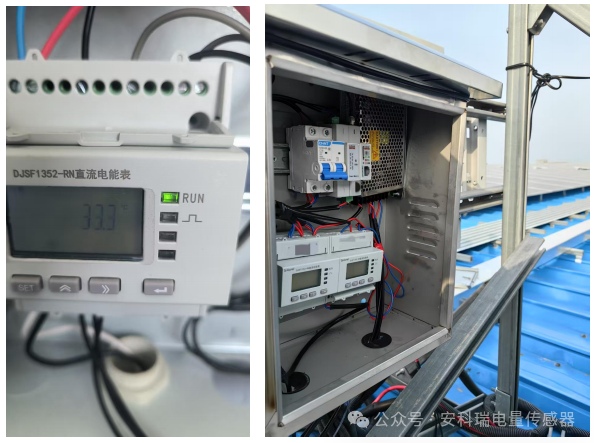

4.1 All-Rounder Product - DJSF1352-RN

The DJSF1352-RN supports dual-channel DC input with adjustable voltage and current ranges, and features a ±12V output to power Hall sensors.

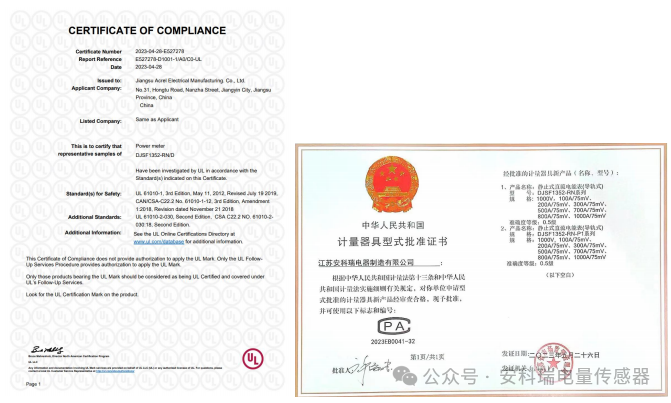

Certifications: Fully certified with CPA, CE, and UL standards.

Communication Compatibility: Built-in protocols include Modbus-RTU, DLT645-07, DLT698, and YD1363, meeting diverse communication requirements across various scenarios.

Applications: Suitable for a wide range of applications such as EV charging stations, energy storage systems, base stations, and DC power distribution, enabling seamless integration.

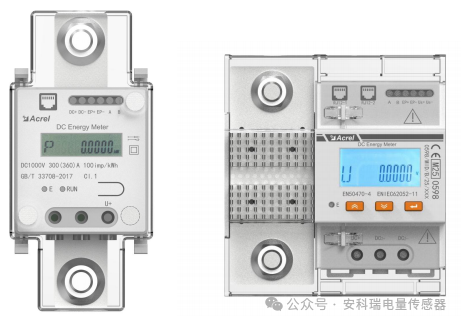

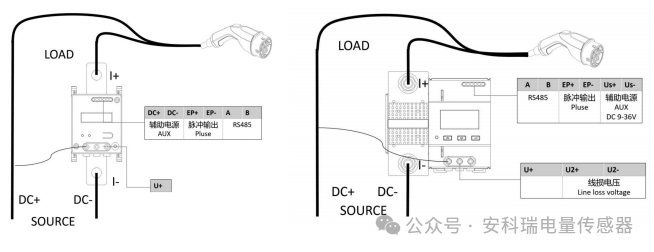

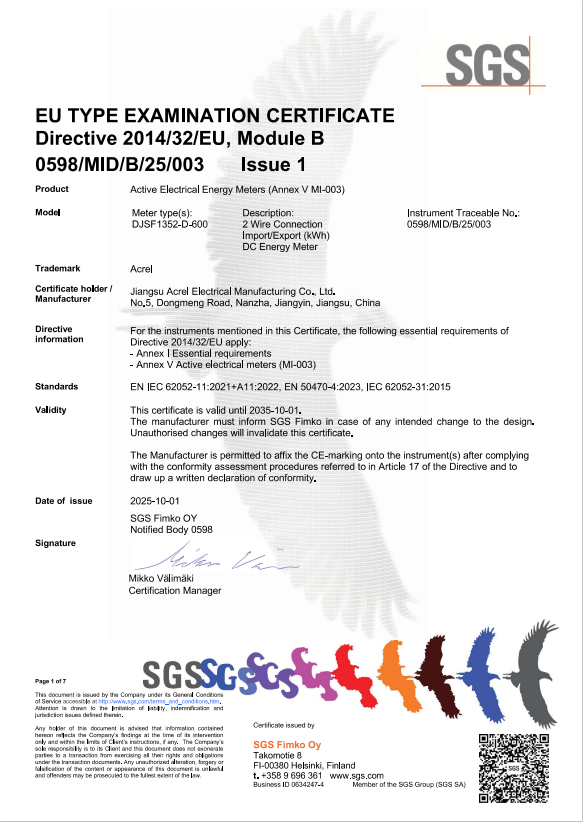

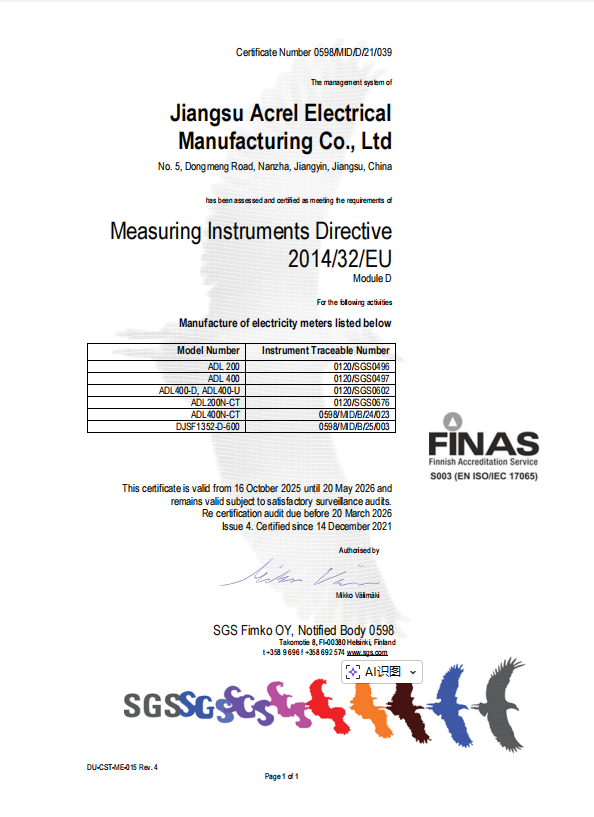

4.2 High-Current Direct-Connection Product - DJSF1352-D

The DJSF1352-D is available in two specifications: 360A and 600A.

Certifications: Certified with MID standards for 600A type.

Temperature Adaptability: Designed to operate in temperatures ranging from -40℃ to +70℃.

Communication Compatibility: Built-in protocols include Modbus-RTU, DLT645-07, and DLT698.

Applications: Specifically designed for DC EV charging stations.

4.3 High-Voltage Energy Storage Dedicated Product - DJSF1352-RN-6

The DJSF1352-RN-6 supports dual-channel DC input with adjustable voltage and current ranges, and features a ±12V output to power Hall sensors.

Communication Compatibility: Built-in protocols include Modbus-RTU, DLT645-07, and DLT698, meeting communication requirements across diverse scenarios.

Feature-Rich: Offers optional analog output and supports wireless module expansion.

Applications: Specifically designed for 1500V energy storage systems and photovoltaic (PV) systems.

4.4 Panel-Mount Integration Solution - PZ72/96L-DE

The PZ72L-DE and PZ96L-DE models offer an optional ±12V output for powering Hall sensors.

Installation: Panel mounting design.

Communication Compatibility: Built-in protocols include Modbus-RTU, DLT645-07, and DLT698, meeting communication requirements across diverse scenarios.

Applications: Suitable for 1000V energy storage systems, PV systems, and DC power distribution systems (the 96-size model supports up to 1500V).

4.5 PV String Monitoring - AGF-MT

Convenience: Reduces cabling from the photovoltaic array to the inverter, optimizing system structure.

Safety: Uses a terminal/puncture connection method for the main current (rated below 20A or 30A), ensuring high safety and easy installation.

Applications: Designed for 1500V centralized photovoltaic power plants.

4.6 PV String Combiner Monitoring

5. Supporting Sensors

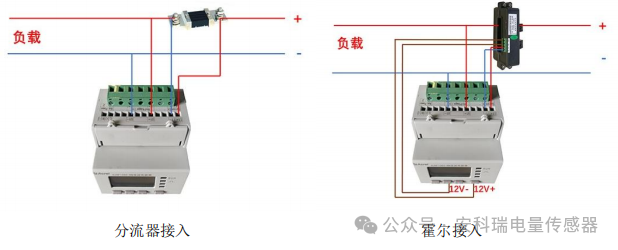

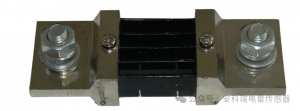

5.1 Shunt Resistors

Advantages

Simplicity and Cost-Effectiveness: Shunts operate on a simple resistance principle, making them generally inexpensive and easy to implement.

High Precision: Under ideal conditions, shunts can provide very accurate current measurements.

Direct Measurement: Shunts measure the current passing through the resistor directly, ensuring a rapid response to immediate current changes.

Wideband Characteristics: They maintain stability across a wide range of temperatures and current levels.

Disadvantages

Heat Generation and Energy Loss: Shunts generate heat as current passes through, leading to energy loss.

Voltage Drop: The measurement process causes a certain voltage drop, which may affect circuit performance.

Size Limitations: For high-current applications, shunts may require a larger physical size to prevent overheating.

Environmental Sensitivity: They are relatively sensitive to external environmental factors (such as temperature and humidity), which may affect measurement accuracy.

5.2 Hall Effect Sensors

Advantages

Non-Contact Measurement: Hall sensors detect current via magnetic field induction, requiring no direct electrical contact. This eliminates additional voltage drops and energy losses.

Suitable for High-Current Measurement: Due to their non-contact nature, Hall sensors are ideal for measuring large currents.

High-Temperature Tolerance: The performance of Hall sensors is less affected by temperature fluctuations.

Flexibility and Safety: The lack of direct circuit contact makes Hall sensors more flexible and safer to install and use.

Disadvantages

Higher Cost: Hall sensors are typically more expensive than shunt resistors.

Complexity: They require more complex signal processing circuitry.

Limited Sensitivity: In low-current applications, the sensitivity of Hall sensors may be inferior to that of shunts.

Interference Issues: Hall sensors can be susceptible to interference from external magnetic fields, potentially affecting measurement accuracy.

Post time: Jan-28-2026