1. General

With the promotion and application of substation automation technology, there are more and more unmanned substations. The high-voltage switchgear in substations adopts a fully sealed structure, and in the course of long-term operation, parts such as switch contacts and busbar connections heat up due to aging or excessive contact resistance, and because the temperature of these heating parts cannot be monitored, the operating conditions of the equipment are getting worse and worse, and the probability of equipment accidents such as burning at the drawer inlet and outlet sides and inlet cabinet contacts in low-voltage switchgear increases greatly. Therefore, it is very necessary to carry out safe temperature monitoring and intelligent control. In this regard, our wireless temperature measurement series products for long-term temperature monitoring of each electrical node, can effectively avoid serious failure, resulting in personal injury and economic losses to users.

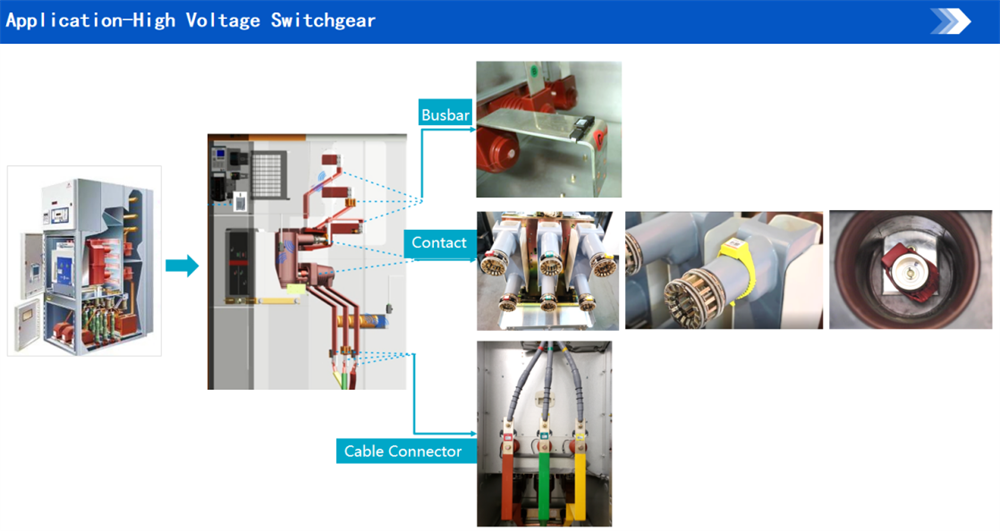

2. Application in High Voltage Switchgear

• Cable connector temperature measurement

• Contact temperature measurement

• Busbar temperature measurement

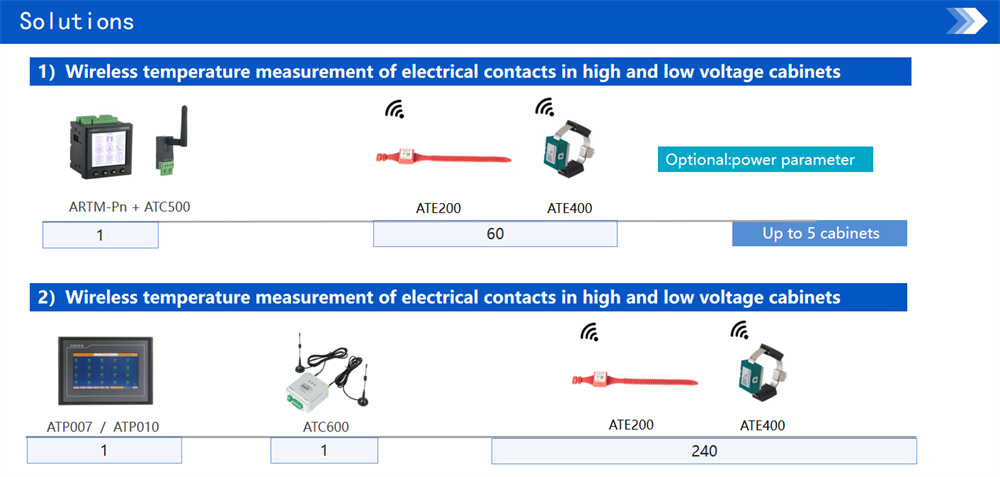

Solution:

Quick product selection:

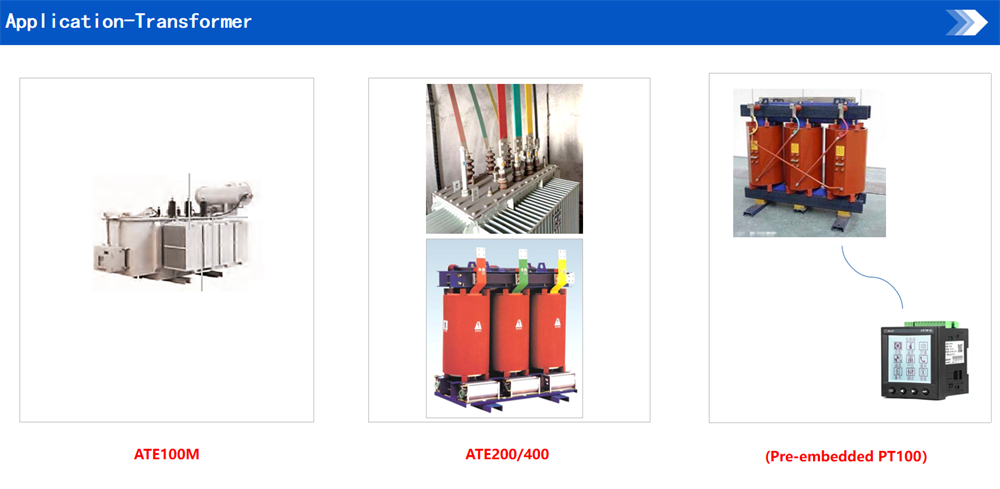

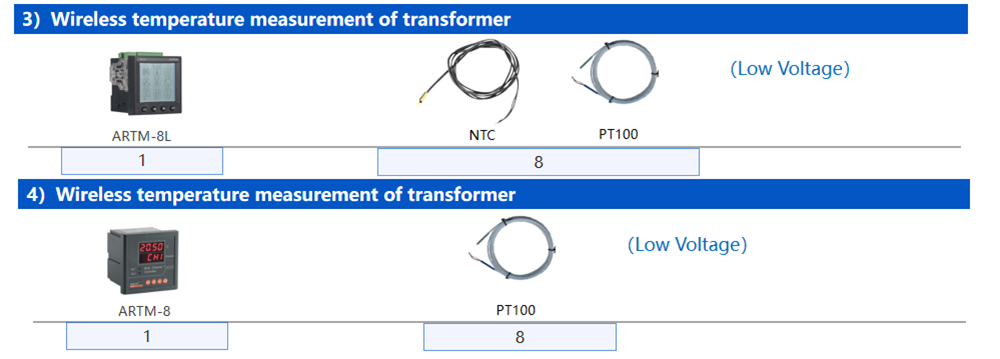

3. Application in Transformer

• Transformer surface temperature measurement

• Transformer connector temperature measurement

• Transformer internal winding temperature measurement

Solution:

Quick product selection:

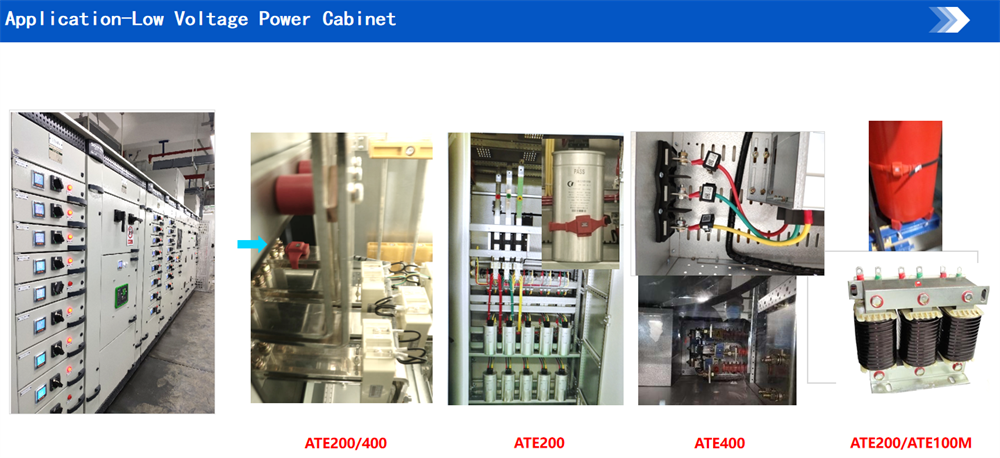

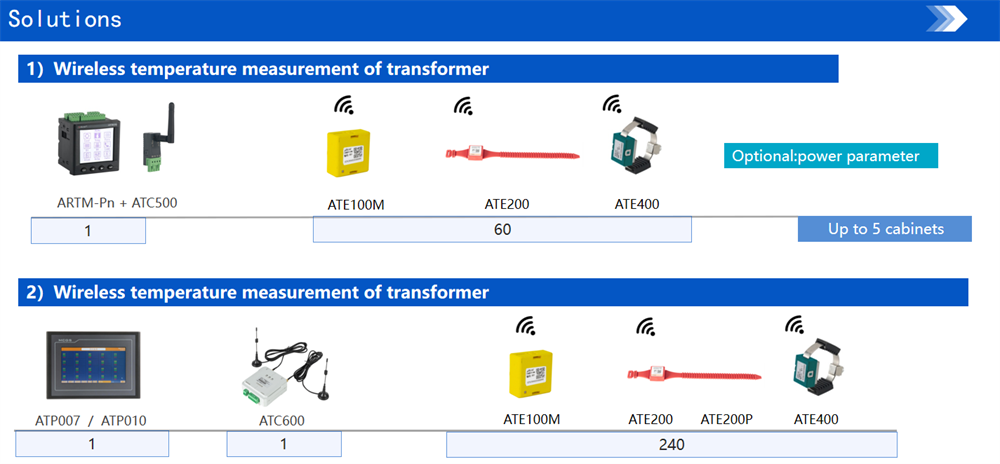

4. Application in Low Voltage Power Cabinet

• CB connector/busbar temperature measurement

• Capacitor surface temperature measurement

• Cable joins temperature measurement

• Reactor surface temperature measurement

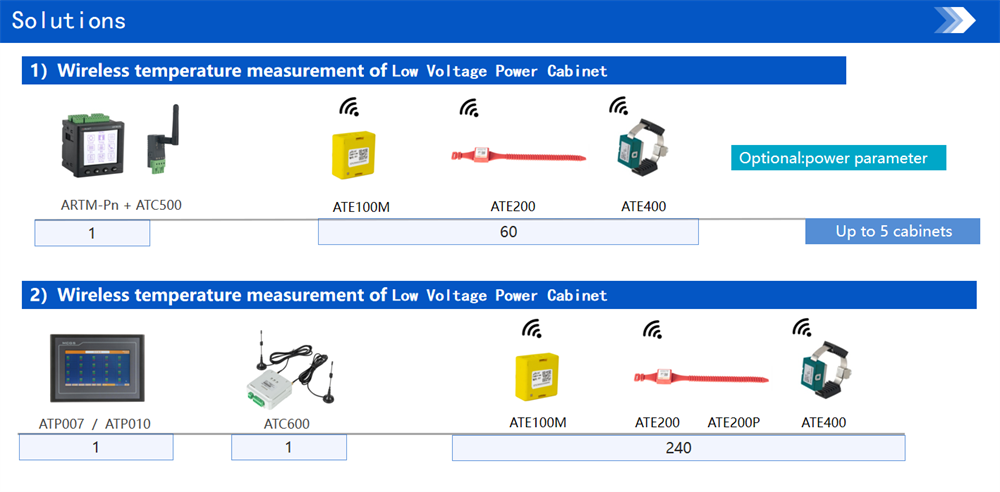

Solution:

Quick product selection:

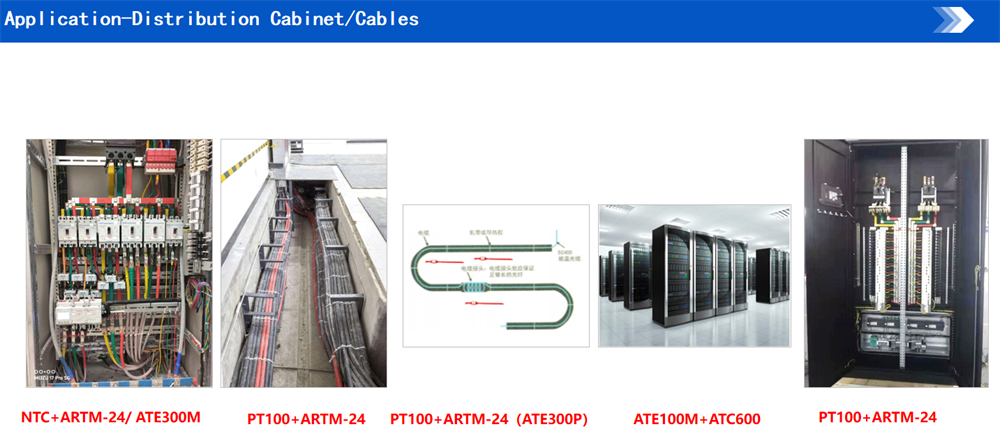

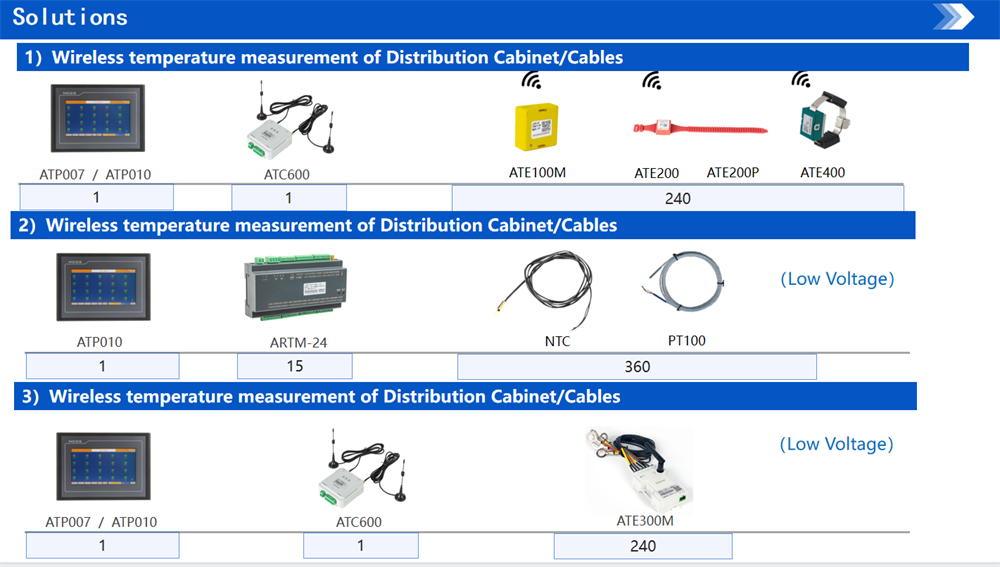

5. Application in Distribution Cabinet/Cables

• Terminal distribution cabinet temperature measurement

• Cable trench temperature measurement

• Indoor long cable/bridge/busway shell temperature measurement

• Data center server temperature measurement

• Data center cabinet connector temperature measurement

Solution:

Quick product selection:

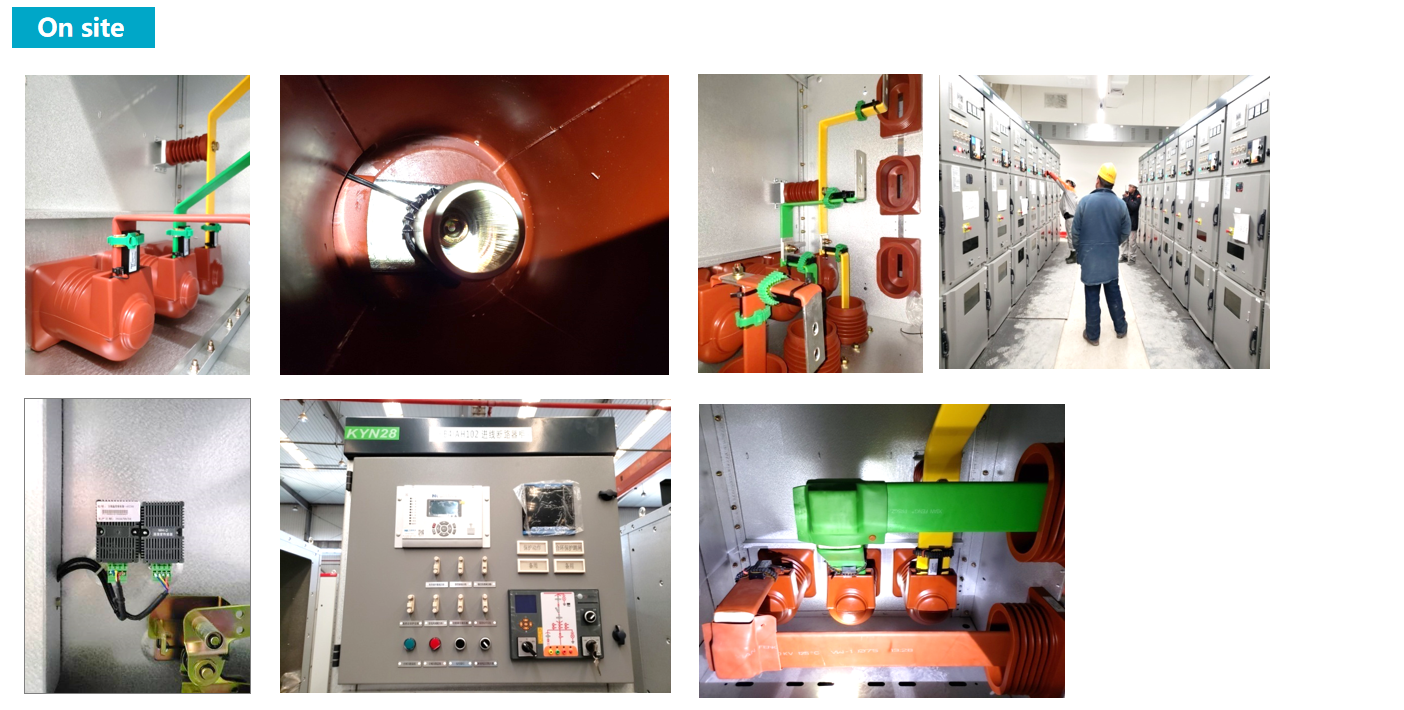

On-site Picture:

In summary, to prevent the contact resistance increasing and contacts overheating formed during operation due to oxidation, loosening, dust and other factors that cause the safety hazards , improve the safety and security of equipment, timely, continuous and accurate reflection of equipment operating conditions, reduce the rate of equipment accidents, high and low voltage switchgear within the cable joints, circuit breaker contacts, knife switch, high voltage cable intermediate head, dry transformers, low voltage high current and other equipment temperature monitoring is very necessary.

Post time: Apr-29-2025